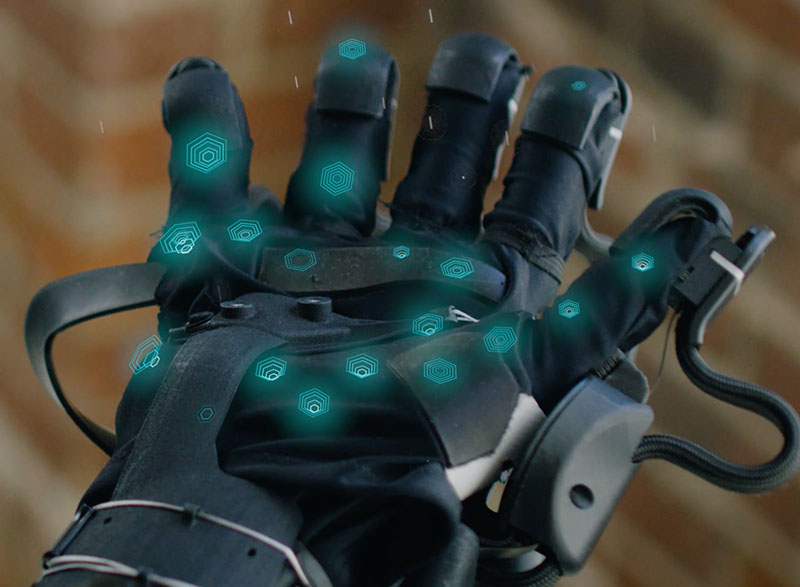

HaptX gloves

HaptX Gloves provide a truly immersive VR experience through haptic technology, allowing you to “feel” the virtual world for applications such as telerobotics, virtual training, virtual design, gaming, and more. As the first product from HaptX, the company faced a challenge with the Gloves that many small startups run into: successfully moving from R&D to commercial product. In the fall of 2018, HaptX approached Synapse with an ambitious plan to quickly productize their proof of concept and turn it into something that could be feasibly manufactured at scale by the end of 2019.

HaptX Gloves bring touch sensory to VR through a combination of detailed tactile feedback, force feedback, and precise motion tracking. A proprietary haptic algorithm models your physical interactions in the experience, and in response, an array of microfluidic actuators push against your skin, displacing it the same way a real object would. The result is an incredibly realistic interaction that enables users to feel the shape, weight, texture, and movement of virtual objects.

Approach

Although HaptX initially came to Synapse looking for end-to-end product development support, our team recognized the importance—particularly for a startup looking to raise venture capital (VC) funding—of scaling our approach in an agile way. By clarifying requirements, identifying the highest risk elements, and providing feedback, we were able to strategically align our engagement to increase efficiency and cost effectiveness.

Navigating from R&D to product realization

The HaptX design team successfully made a proof of concept, but productization had been difficult for them to tackle on their own. The challenges? Gaps in experience, and the sheer complexity of the HaptX Gloves (small parts, high part count, a challenging-to-manufacture tactile laminate layer). The Synapse team dove in and identified the areas of expertise that needed to be filled, kicking the project off with conducting a productization and manufacturing audit. From there, our engineers guided prioritization of feature sets given HaptX’s needs and milestones with recommended development paths and potential product roadmaps beyond the V1 prototype gloves.

Over the course of the project, the Synapse team:

- Optimized the following key elements for reliability, cost, manufacturability, and accuracy:

- Tactile touch, pneumatic system integration, softgoods fit, don and doff, ergonomics, human factors for size of hands, integration with finger tracking subsystem, force feedback

- Provided supply chain strategy to address sourcing requirements, capabilities, materials, location, and product fit

Applications

With HaptX Gloves, users can test out a car before its manufactured, control a robot on the other side of the globe, or even gain hands-on first response training. The combination of VR technology and haptic feedback utilized in HaptX Gloves unlock immersive, novel experiences and applications. It’s a haptic solution for professional design, training, and more.

Summary

Synapse helped HaptX bridge the gap from research to commercial platforms and building products at scale…while bringing humanity to technology. HaptX Gloves illustrate the vital progress being made in shaping technology that utilizes powerful human senses to unlock novel experiences. Since reaching productization, HaptX received positive comments from Jeff Bezos at Amazon re:MARS 2019, was selected by UploadVR as the 2020 CES Best of Show winner, and raised $12 million in new funding. What’s next? Getting HaptX Gloves into companies around the world.