Using data for reliable power generation

IoT meets the power plant

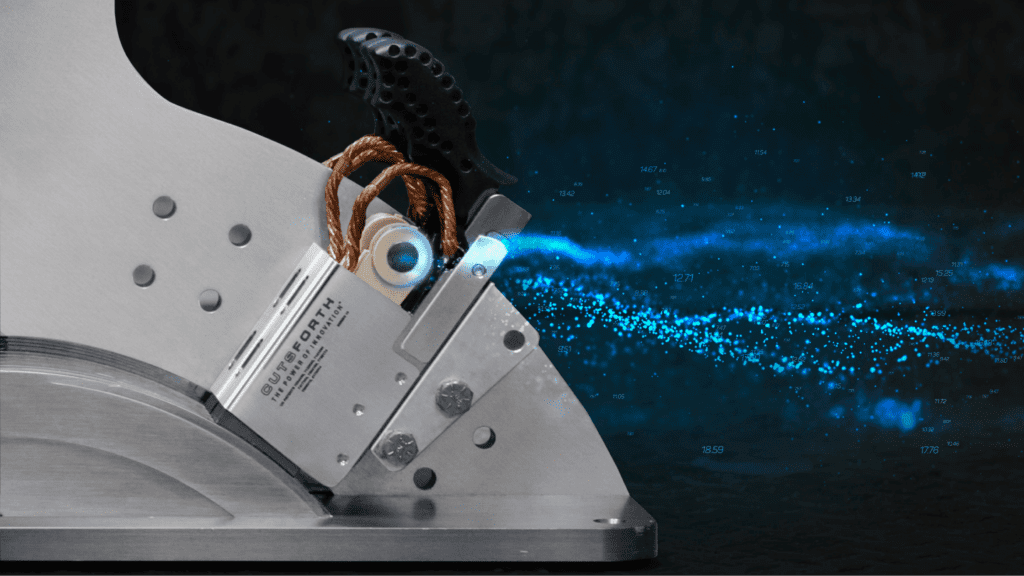

Cutsforth™ Inc. makes aftermarket brush holders for generators and exciters. Carbon brushes provide essential electrical contact and current to the generator, and worn-down brushes pose a danger if not replaced in time. Cutsforth serves some of the world’s largest power companies. Its flagship “EasyChange Brush Holder®” product enables the replacement of worn consumable carbon brushes simultaneously while a generator is running.

Cutsforth saw an opportunity to go further, bringing predictive maintenance services to its clients and sought unique expertise in IoT to help invent an ultra-low power measurement sensor, design a wireless system to aggregate the information from hundreds of sensors across a plant and generate real-time automated maintenance alerts. They needed a team under one roof. They needed a global team of experienced disruption experts spanning business strategy, experience and design, sensing and wireless engineering and data analytics.

“Our project required quite a few things…mechanical, wireless, software for interaction, and ultra-low power consumption…in working with this team, we found all of the disciplines we needed in one outfit.”

— Rob Cutsforth, CEO, Cutsforth, Inc.

New boss at the power plant: data

Project highlights

Challenge

Saying no to complexity

Brush replacement involved intricate inspection to assess key features which, if missed, could lead to fires, offline generators or slowed electricity flow. This meant locating and inspecting as many as 200+ brushes per generator.

Solution

Engineering that solves

Our experts invented a novel sensor that understands and communicates details like brush length, in real time, to a custom hub, alerting when brushes need to be changed. Now, there’s no longer a need for manual inspections.

Setting sights on sensors

The sensor measures many other data points of the generator’s operation, alerting users to out-of-range parameters. This helps teams manage generator performance and address issues before they become catastrophic.

Outcomes

Near and long-term benefits

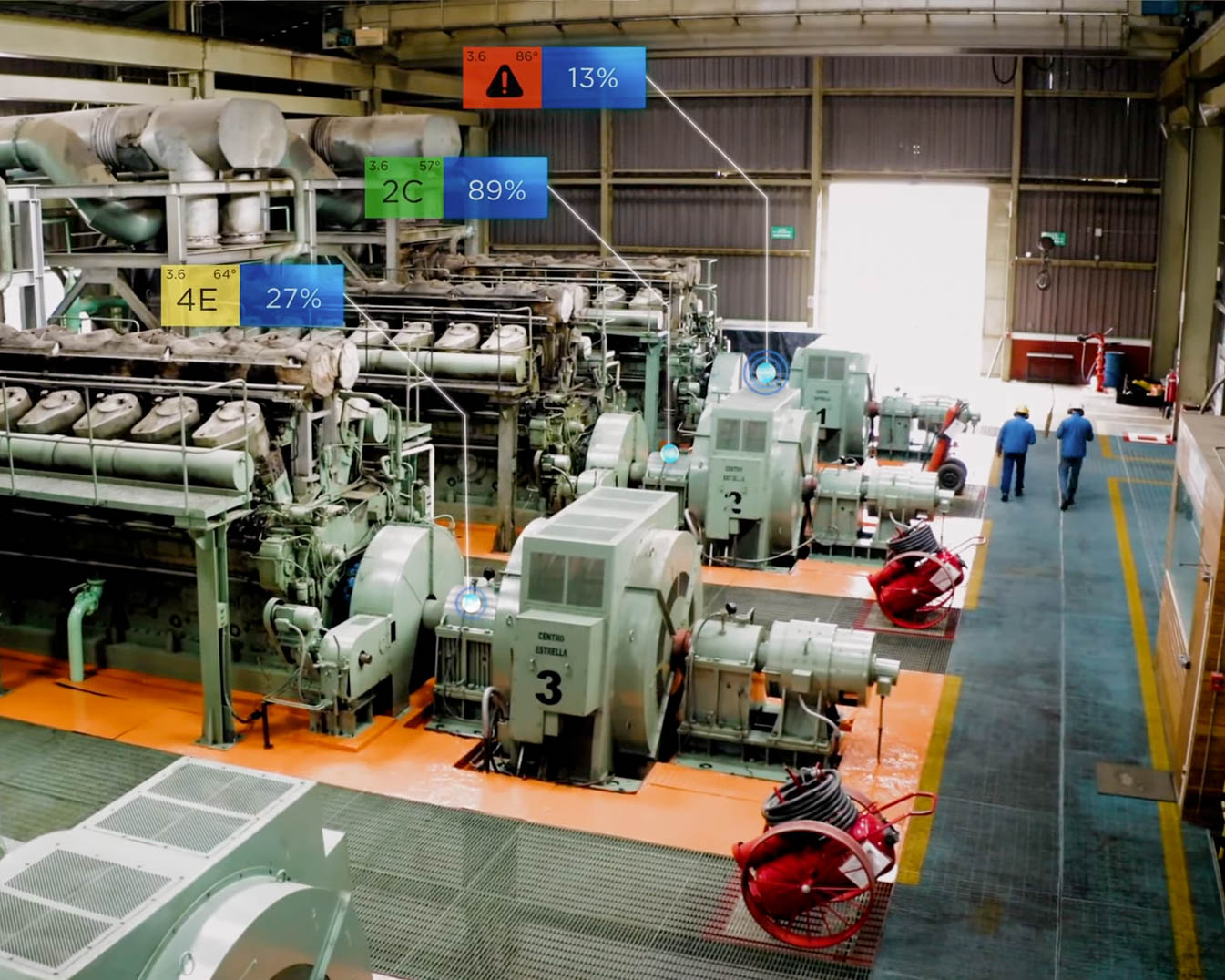

Today, Cutsforth’s customers can remotely monitor brush and generator health, enabling maintenance teams to proactively manage service and resource needs.

Breakthroughs start small

Now, power generation facilities using the Cutsforth system are modernizing their operations, achieving operational excellence, and providing more reliable and consistent power to meet customer demands for the energy needed to support their modern lifestyles.

Synapse offers a one-stop-shop of uniquely combined talent to accelerate the launch of new products, services and business models. Our unique five-part industry knowledge, all in one place, enables us to occupy a leading position as an established builder of impactful connected device ecosystems worldwide.