Putting atmospheric CO2 to work

Reinventing the carbon economy

While it’s a fact that CO2 is a harmful greenhouse gas that causes climate change, it is also a valuable industrial commodity that is widely used in a range of applications including food packaging, indoor agriculture and beverage carbonation. In addition, there are many promising

technologies that enable the conversion of CO2 into plastics, chemicals and building materials such as concrete andcarbon fiber. An unfortunate reality is that the process of producing and distributing CO2 can emit significant amounts of the gas into the atmosphere — two or more tonnes emittedfor every tonne delivered.

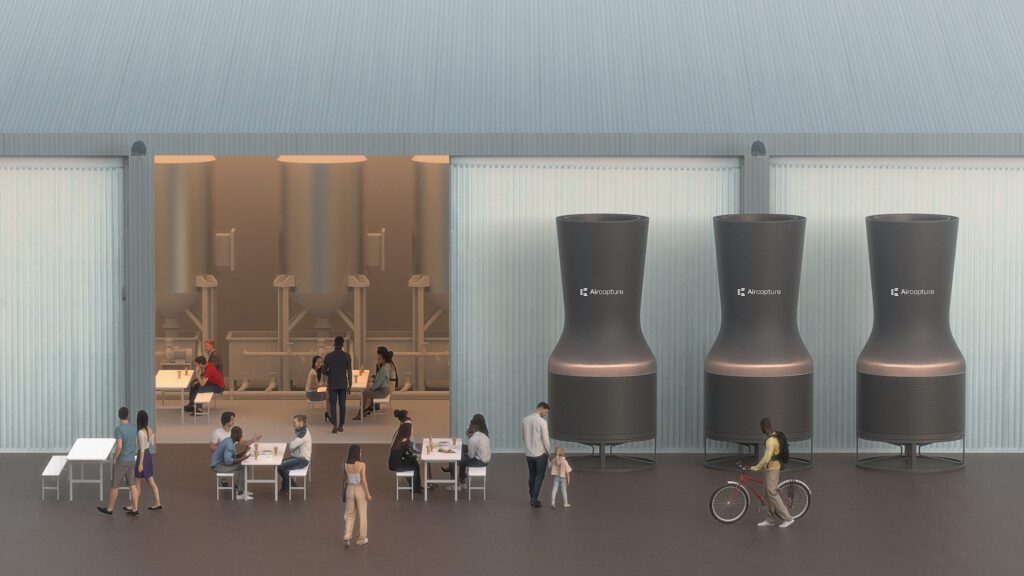

Aircapture is addressing this problem by developing and commercializing DAC (direct air capture) systems that enable businesses to capture atmospheric CO2 at the point of use, using waste energy available from the customers’ existing processes. They partnered with us to optimize their system design, improve key performance metrics, enhance manufacturability, and develop a design vision.

Clearing the air

The Aircapture system works by using bricks with thousands of small channels through them and a chemical coating that absorbs CO2. When the air travels through the bricks, the tiny holes provide a large surface area where a substantial portion of the CO2 is absorbed. Low temperature steam is then used to release the CO2, which is then processed and stored for use.

The design target for the prototype was to build a 100-metric ton of CO2 per year system. To accomplish that, our team of engineers established the system architecture, performed extensive computational fluid dynamic modeling, simulated airflows, and conducted adsorption/desorption kinetics modeling for process optimization while our design team created industrial design concepts that humanized the new technology. The resulting design enabled Aircapture to build its first system to demonstrate functionality, optimize processes and operational parameters, and also gain commercial traction with investors and customers.

Creating and scaling a circular carbon economy

The impact for Aircapture’s customers and the planet will be significant. Businesses around the world will have a reliable source of carbon neutral or carbon negative CO2 without the financial and environmental impacts of traditional production and delivery methods.

We’re proud of our partnership with Aircapture and look forward to developing many more innovative solutions in the fight against climate change.