Robots are the future — but how do we get there? What can we do to facilitate the creation of a future where robots can do good?

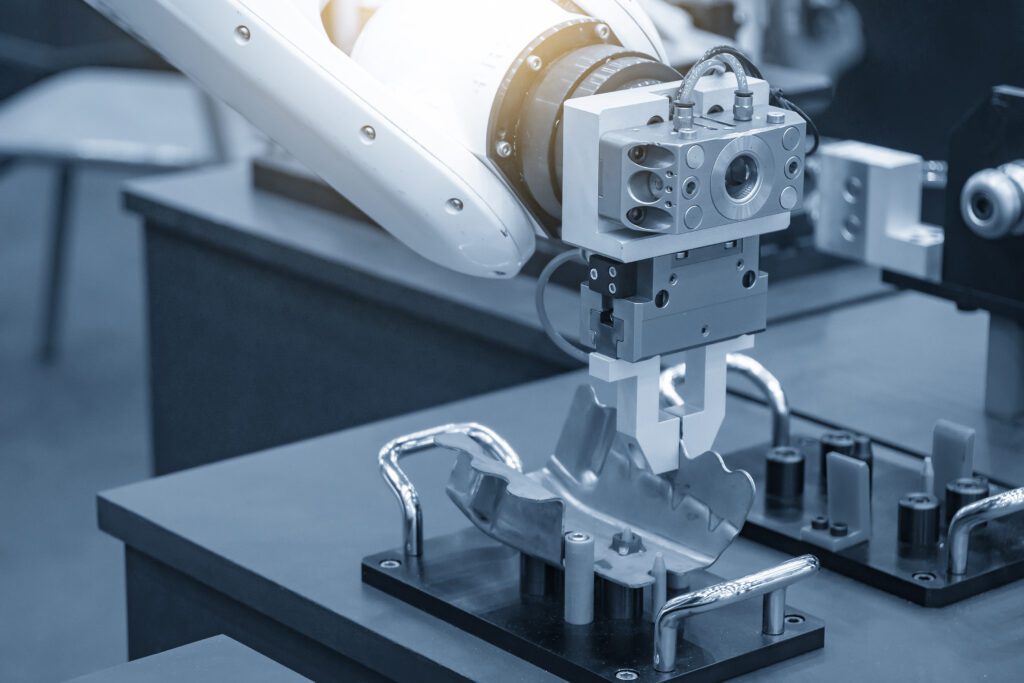

We’re not yet at a point where we have robots as flexible and smart as humans, but we can put them in more hazardous areas and run them 24/7 to help work through menial tasks. One opportunity to use robotics for good could be for sorting and separating physical components to facilitate the realization of a circular economy.

Fundamentally, one of the goals of a circular economy is to remove our reliance on finite resources by reusing, repairing, remanufacturing, and recycling existing materials and products as long as possible. Apart from reuse, each of these processes require some product disassembly to separate components, which can be a limiting factor for implementing these strategies.

Disassembly typically requires labor, which costs money, and can be a financial barrier to implementing circularity strategies. Robotics are often touted as a solution to prohibitive labor costs and seem like an attractive solution to disassembling products for repair, remanufacture, component reuse, or recycling. For example, look at the Apple Daisy robot used to disassemble iPhones for recycling.

However, there are limitations to what a robot can do. Robotic disassembly is typically destructive as the limited flexibility and adaptability of the robotics cannot compensate for the lack of design for a disassembly process. This limits the value that can be extracted from the product, with components going directly to recycling instead of being reused in other products.

If even Apple ( the highest valued company in the world) cannot make a robot yet that elegantly disassembles their products without damaging components, then what is the next step for robotics in this space?

The biggest opportunities lie in product design.

— Will Harrison

I would suggest that the biggest opportunities lie in product design. If products are designed for automated disassembly, the cost of recapturing valuable materials and components at the end of life can drop dramatically. Designing for automated disassembly is also likely to facilitate automated assembly — reducing the cost of the assembly of the product too.

Robotics have a huge potential in this area, but they work best in constrained environments. Designing the product appropriately for disassembly involves constraining the factors that the automation and robotics have to accommodate — this is key to unlocking automated disassembly. Imagine a future where a product is designed such that it can be sent back to the manufacturer for repair, where a person simply places it on an automated line that relies on a robot to disassemble the unit, test the components, and replace the necessary components to get the product working again. A demonstration of this concept is shown by molg.ai, and I’m excited to see where it goes next.

Robots aren’t yet flexible or smart enough to delicately tear down product components for reuse (like humans can), but they can run 24/7, refurbishing, repairing, and extracting valuable materials for recycling from products we have designed. As with all sustainability challenges there isn’t a single strategy that will solve the challenge of disassembling, repairing or refurbishing a product at the end of its life. The solutions should consider the whole system and all the stakeholders, with the product designed appropriately for every step in its lifecycle, from assembly, to use, to robotic disassembly and repair.